I have been keen

on the GE AC4400's since I saw the first one in CP colours. I just

had to have one. My First new locomotive for my collection

was the CP 4400. I detailed this locomotive with only a few after

market details. I made most of the grab irons myself. I used

manufactured drop grab irons for the nose and the back end. The rest

I made myself.

|

Since I did this one I have found many after market detailing parts for the C44-9 / AC4400 's. I have in my collection, 4 of the locomotives. I have a CN Rail C44-9, CP Twin Flags AC4400, and the GE Demo Units for both. The detailing on these units was getting better with each one. When Athearn announced that they were going to be doing the 4400 in the new Beaver Herald scheme I was thrilled. I realized that this was probably going to be the last 4400 I would be getting. Definitely the last CP Rail 4400, so I wanted this to be the best one in the collection. This new Loco would have all the detailing I could find. Now I detail based on what I see on the real locos. If I can't see it then I don't add it. Therefore I don't add all the under frame parts that are available. What is the point of putting black parts on a black frame that is in the shade when the loco sits on the rails.

I picked up the new loco on my B-Day and brought it home. Again Athearn has done a great job on the Loco. There are some things that are missed. If I can find Unit number 9623 I will be able to compare the Prototype with the model. But I have seen on other ones that the white reflective line that runs down the side of the walkway is a broken line not the solid one that it comes with. As well, the RCMP musical ride crest has been returned to the same location on the side of the cab but now it is smaller. When the paint scheme was first rolled out it matched what Athearn has released. As the Loco's have been repainted and touched up CP seems to be updating the markings. The final discrepancy with the unit is the back up light. CP uses single lenses instead of the dual lenses that the Loco comes with. This is an expected deviation since the rest of the world seems to use dual lights. It was now time to start adding parts to the unit. I separated the shell from the chassis and removed the cab and the radiator insert.

The Body Work

Now is the time to start making holes in the shell. I used a fine drill bit in my rechargeable Dremel and drill in the holes for the drop irons on the back and on the cabinet on the fireman's side of the body. This part can be pulled off, making the drilling of the holes easier. The starter box is now available from Details West and this goes behind the converters. this means that you don't have to drill the bottom most set of holes as this is where the starter is. I didn't use the replacement doors that the Starter comes with as this would mean re-decalling that side. Unless you are down 2 inches from the loco you won't even notice the old doors that are actually to long. There is a small straight grab iron above the cabinet that is at a 45 degree angle that is easy to miss. CP also has installed three grab irons directly behind the fireman's back window that have no marking points. One is on the roof right in front of the dynamic brake covers, these are the three covers that have the black labels with white lettering. The other two are on the side directly below the roof one and are spaced evenly apart. I cut out the recessed area on the exhaust stack base and glue the silver stack directly to the hood. The horn is incorrect for CP but a few swipes with an Exacto knife can rearrange the bells into the appropriate layout this will save you a few bucks. The starter box sit on the walkway directly below the C in Canadian. The Pilots are quick and easy to do. First slice off the three tabs on each side for the M.U. hoses. This is where part number MU-266 go. Drill out the center tab for the mounting pin in the part so that the hoses are centered over the old location. Do the front ones first then the back ones. Still on the back pilot mount the Spare knuckles outside of the hoses and with the bottom of the knuckle flush with the detail on the bottom of the pilot. On the front pilot the plow (PL-140) is all that has to be mounted. Very carefully bend the hoses up and out so that the hoses will slide through the holes in the plow. I don't use the template to mount the plow. I have a piece of track and I eye the location for the proper amount of clearance. Before gluing the plow I remove the mounting pins off the back. I also install the front railings because if you don't you will never get it on with out removing the plow. This is when I made a wondrous discovery. I opened the little envelope to get the railings out and lo and behold, two McHenry couplers fell out. This was completely unexpected and allowed me to return the couplers I had pirated off of another Loco. I really Like McHenry couplers. I find they are strong and have never had one fail. Of course they don't take being dropped on the floor when mounted to cars and I have lost 3 that way so far. On the upside to that it is only the coupler that gets damaged, not the draft gear. On went the railing and then the plow. The plow was painted gloss black before it got mounted. All that is left is the ditch lights. The installation of these will be covered in the section on lights.

The Radiator Work

I tried to follow the steps that came with the grill details from Details West but found them hard to understand. I would have liked to have a diagram to show me what they were talking about. I didn't want to mess up the radiator so I just glued the detail over the existing detail on the model. The walkway goes on with out a problem and the instruction for that are straight forward. I placed the part back into the hole where it came from and drilled the two holes for the grab iron on top of the rearmost walkway. This lines up with the grab irons coming up the rear.

The Cab Work

The Cab requires the most work. First is to remove it carefully from the rest of the body. This is done best by gently pulling the front tab back while pushing it up. Once the Cab unit has been removed, remove the windows. Two of the side windows have to be pushed into the cab as well as the front windows. I now drill out the mounting holes for the grab irons on the nose and the roof. The remaining grab irons have to drilled out from the inside, if you look closely the holes can be seen. I broke my drill bit doing this and had to resort to using a needle that I heated up with a candle. I found that this method worked better than drilling. Put the grab Irons on before you do the windows as the oils left behind on the glass will attract the fumes for the CA glue and cause frosting. I discovered this aspect of CA glue when working on my B5 Star Fury, I went through two canopies on it before I figured it out. The four large grab irons on the sides of the nose have to be hand made but the is really easy to do. The two grab irons over the front windows have to be installed after the windshield wipers. I used A-Line small wipers. This gives two extra wipers which is very helpful as they like to go for a flight when being released from the trees. Once the glue dries the windows can be placed. Before starting paint the openings, black for the front, small side, and rear windows as well as the door window on the nose. Silver is applied to the square side windows. The silver on the side windows is also applied to the raised detail area around the windows. Once the paint has dried the windows can be placed in the openings. I use Humbrol's Clearfix to help the clear pieces stay in place. Getting it on the windows isn't a problem as it dries clear. I also use this for fixing the bulbs in place as well. Leaving the adhesive covering on the outside of the windows is a good idea as it will help protect them during handling and painting, but the front and rear coverings have to come off so the wipers can be placed. Once the wiper blades are on, the over head grab irons can be placed. Three sinclair antennas are placed on the roof. For the proper location stand on a bridge when a 4400 is going underneath. I think mine are misaligned, but seeing as most people don't see the roof of the locomotive it isn't big deal. Anyone who bends over to have a close look and nitpick is to be smacked the the spare 2x4 from the bench work. Remember, this is your loco and if you are happy with it that is all that matters. That now wraps up the body detailing.

The Chassis Detailing

This is where I do the least amount of detailing. As I mentioned above. Putting black details on a black area that is in the shade makes no sense at it can't be readily seen. I do the basics here. I place the shocks and the brake cylinders. Beyond that it is pointless I think. There is a lot of room for detailing on the chassis and trucks. But the trucks are an area of high use when the loco is put on the tracks so if you are taking the loco on and off the tracks. For example I store my loco's on display shelves when I am not using them so I am always handling the trucks when I place them on the tracks for use. I am in no rush to mount some of the standard equipment on the trucks like the speed recorder cables or brake chains for the simple reason that as I sit here typing this page I can not remember seeing them on any of the loco's that I have seen at Ayleth Yards here in Calgary. I am sure that they are there, but they are hard to notice with out closer examination.

Fuel Tank

Railings

I decided, at the same time I was updating the air tanks, that I would fix the railing discrepancy above the capacitors. CP has raised the rail up and changed the shape of it above the starter box. Using the original railing as a template I bent some brass rod to the proper shape. I carefully drilled new mounting holes for that railing and the second lower railing that is half way between the walkway and the new railing. This one was the original railing trimmed back to fit. The stanchions are out of the spares box and are longer than the originals. I trimmed and bent the mounting pin and placed them in the original holes. Now all to do is to paint it.

Adding the Lights

The ditch lights are Details West Lights that come with light bulbs. I don't like the bulbs they come with as there is to little wire to work with. I replaced the bulbs with one I buy at Trains & Such here in Calgary. They are 1.5 volt bulbs, I use the same bulbs in the nose lights as well. I started by fitting the platforms in place flush with the deck with CA. I left it overnight to cure properly. The next day I drilled down and back through the deck and pilot. I fed the wires down through the holes in behind the pilot where they will be soldered to the wires from the nose lights. The light box is then mounted and the bulbs aligned with in them. I don't put the back on as it doesn't fit well with the different bulbs. I use putty on the back to stop light spillage and then paint them to match the rest of the mount. The directional lighting is done with Diodes and is adapted to fit onto the Athearn clip. I only put headlights on as the only time the loco will be going backwards it will have another Loco in front of it. All my main Freight Engines are like that.

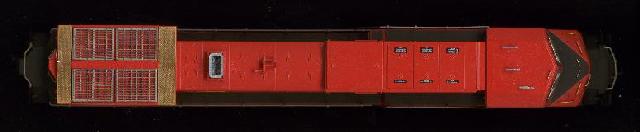

The Loco is now ready to paint. Here it is before the painting started with the detailing in place. At this point all that is left to add is the ditch lights and the starter box.

Ready To Paint

The painting is straight forward and all done with a brush. I found that the the best matching red paint is " #16-36 Southern Pacific Daylight Red" manufactured by Badger in the Model Flex Line of paints. I applied this right over top of the metal on everything but the stanchions. I did a test on those and the size of them causes the red to become to dark. I painted the stanchions with white (H1) before I applied the red. After it was done I realized that a light grey would have been a better under colour to use. The rest of the details were painted with Aqueous Hobby Color paints. Flat Black was used on the railings, truck sides behind the wheels. Gloss black (H2) was used on the pilot details. Metal Black (H28) was applied to the wheels themselves. The details on the fuel tanks is painted white first then red. I used a different shade of red that the body colour. This can be any red that you have laying around.

I like my loco's to have a fresh look so I don't do a lot of weathering. I might do a light soot forward and back from the exhaust stack but that will be the extent of weathering. As I have the loco longer I will add weathering. This way they loco's age as they would on the real RR.

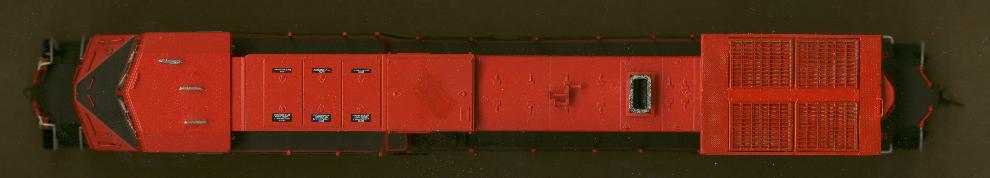

Here is the Loco with the painting done. I place it on the scanner and then did the scanning. This work fairly well unless I want a head on or full rear shot.

Parts List

|

|

|

|

| CE-269 | Starter Box & Doors | Details West |

| CE-270 | Radiator Walkway & Lugs | Details West |

| 2724 | Radiator Grill | Details Associates |

| PL-140 | Snow Plow | Details West |

| MU-266 | MU Hoses (3 cluster set) | Details West |

| DL-243 | Ditch Lights & Platform | Details West |

| SK-196 | Spare Knuckle & Bracket | Details West |

| SY-2224 | Grab Irons 11" straight | Detail Associates |

| SY-2202 | Grab Irons 17" Drop | Detail Associates |

| #29201 | Windshield Wipers (short) | A-Line |

| AT-261 | Ari Tank detail kit for bottom mount brackets | Details West |

| 238 | Laser Cut Windows | AMBI |