|

|

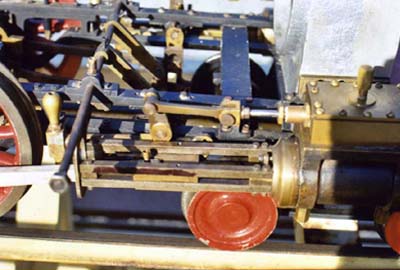

Photos taken September, 2009. Photo on right shows recently installed crosshead pump.

10/04/09 The boiler has been ordered. While I do have a used copper boiler that I purchased years ago, it leaked badly it was questionable if it could be repaired. To be on the safe side I felt it would be best to have a new boiler. While I'm waiting for the boiler I've started working on several small items such as the front coupler. The pipes that deliver the steam to the cylinders have also been installed.

There has been a bit of a set back - a piece of the smoke box casting spit off. A close inspection uncovered an additional crack in the casting which is made out of aluminum. A plate of aluminum was purchased and cut to the proper shape. The next step will be to find some one to weld it back together and attach the aluminum plate so hopefully it will never break again.

6/23/10 Found someone to weld the smokebox back together. I told him there was no hurry as the boiler wouldn't be coming until the summer. I also found and purchased an unassembled pair of archbar trucks several months ago. Even though all the parts were machined, I have had to spend many hours filing and painting the parts. Only a few of the parts have been put together so far. After doing some research in some old issues of Live Steam magazine, I sketched out some plans and purchased materials for a hand pump. It has taken longer than I thought to machine all the parts and put it together.

11/26/10 Hand pump has been completed and I'm starting to add the pipes that will take water in and out of the pump. Looking back, I think I should have just made a larger version of one of the pumps from the magazines. The pump I designed and built does work but it's too complicated, and with the plumbing added barely fits into the water tank.

The archbar trucks for the gondola car have been assembled and painted. I've been looking for a company that offers pin and link couplers with no luck. It now looks like I will have to make my own. A trip out to the Orange Empire Railway Museum to look at some old wood gondola was very helpful and gave me several ideas on how to construct the model. Haven't drawn up a plan yet - I still need to visit some lumber yards and see what sizes of wood are available.

Got word yesterday that the boiler almost finished and that the smokebox has been welded back together.

12/5/12 After my brother pointed out that I hadn't updated these pages in over a year I thought it would be a good idea to do an update.Boiler and smoke box are now on locomotive. The plumbing in smokebox completed - a difficult task given that there is not much space in there. Throttle lever constructed and installed with linkage to the throttle valve. Ashpan, firebox door, and turret have been built and installed. The plumbing to the blower is mostly completed. I found the scale model valves too expensive, so I'm using cheap valves from the hardware store. The rod that forms the handle is removed and replaced with a small round handle made on the lathe. The cab floor has been started.

The frame of the gondola is almost complete - just need to add bolsters. The queen posts - 8 of them - have been machined out of bits of rail. After an unsuccessful search for link and pin couplers I made my own complete with working draft gear (the draft gear is the shock asorber behind coupling).

5/5/13 Cab floor has been completed and reverse lever has been installed. The linkage from the lever to the value gear required a lot of trial and error fiddling as it needed to bend around the drive wheel and up to the reverse lever. At this point I was able to test the engine by taking it down to the club and attaching a hose to fill the boiler with compressed air. Running back and fourth several times I found the locomotive to be a bit slippery but once it gets moving it has no problem pulling me and a tool box. Another test was run with a small passenger and the engine again was able to pull the load without struggling. I did find several leaks - the gaskets in the steam chest, cylinder heads, plus the bolts that held the firebox door had the largest leaks. Several months later I had solved the leaking firebox door bolt problem plus replaced most of the gaskets in the cylinders and steam chest. The engine performed a bit better when I tested it again at the club.

The gondola is now complete enough to be used. Bolsters and trucks have been added and the truss rods with their queen posts are now in place. Stake pockets have been purchased and installed.

The biggest news is that I now have a house with a garage. I finally after all these years have a place for a work shop. Much of my time the last few months has been taken up with moving and setting things up in my new home. The drill press and lathe are now in place, the locomotive stand has been replaced (the old one had termites) and I'm starting to work again on the locomotive.