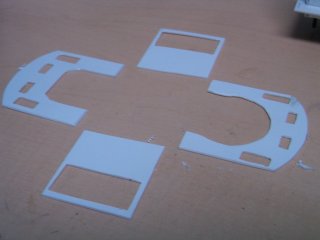

Fig 9 |

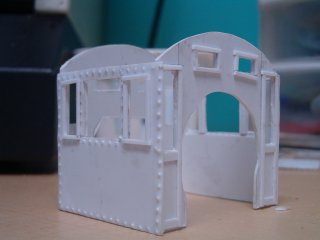

After sitting on the bench for a month, I finally got back round to working on the 2-8-2 which I think I will call No11. I made an abortive attempt at a cab, then didn;t like the way it looked so I trashed it and started over. The 4 walls are .040 styrene with a .001 overlay with embossed rivets. Window and door frames are styrene strip and the roof is a single section of .001 styrene natcherly with embossed rivet detail. |

Fig 10 |

Fig 11 |

| Decided to rebuild the cylinders for a more scale appearance. Basic styrene tubing cut down to fit over the old cylinders. Valve chests built up from styrene strip. |

Fig12 |

Fig 13 |

Fig 14 |

Accomplished some detail work, built up the twin air compressors from styrene shapees and plumed then using .030 rod. Estblished the running boards and air reservoirs as well. Sanding line and injector lines (the injectors themselves will be hidden in the cab.