As time drew near for the Annual Appalachian Model Railroad Society's Annual show, and my completeion of a protable layout to display my 7/8 scale equipment on, I felt a need to have a 2nd locomotive to complement Shay No6. No4 was a bit too lont and had trouble negotiating the curves ont he portable layout, not to mention looking silly with a huge gap between the locomotive and tender. The search was on and I found what I was looking for in "GLOVER STEAM LOCOMOTIVES" by Richard Hillman. It was a small saddle tanker 0-6-0 with beautiful proportions. I just had to have it on the roster!

For those not familiar with the GLOVER name, the Glover Machine Works was located in Marietta., Ga and built some 200 or so steam locomotives. This was more or less a sideline for them, as the built log skidders, hoisting engines, and cranes as well. Their primary product was (and still is, although not in the original facility; it was razed in 1995) pipe fittings for the oil industry.

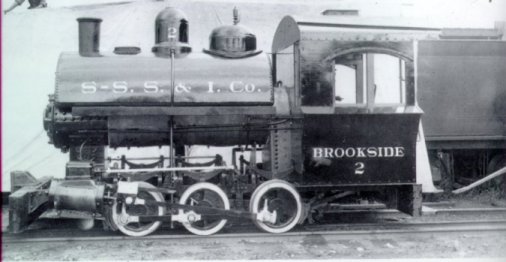

C/N 91417 was ordered in 1917 by the Sloss Sheffield Steel & Iron Co as its No2 named "Brookside." Although this locomotive was standard gauge I used its proportions to make a 2 foot gauge "should-have-been" locomotive.

.

With the frame basics done, I turned

to making a boiler with the right look about it. Using 2.5

inch PVC as a basis I built up the basic form for the firebox.

The smokebox was made from

styrene bits, but the raised lettering was courtesy of Jeff Saxton, laser

cut from plexiglass. A set like this goes for about $4 plus shipping

and handling. You can contact him a jbsaxton@aol.com.

This was truley a distinguishing feature on a Glover locomtive and a nice

touch to the model.

|

|

Returning to the locomotives

'poop deck' it was time to start the cab walls and the interior cab details.

All WCNG locomotives have a complete backhead, and No2 was to be no different.

The engineer figger was to give a sense of scale to the project.

|

|

Since I use quite alot of

these various fittings, I made a mold for general locomotive fittings.

The valves and handles, and the turrent were scavanged from a Bachmann

Shay. The injectors, water glass and steam gauge were created from

my own masters made in house. The Johnson bar and throttle were also

plagerized from the Bachmann Shay. The firebox door and the rods to the

valve gear however were fabricated from styrene.

After

complereting the cab, the model was painted with a dark grey primer , then

a shiney black. I dry brushed on rusty spotches in strategic

locations, and shot it over with a mist of flat black to simulate a sooty,

grimey finish. After that it was time to install the RC (a matter

of 2 wires) lube the mech up, and stick in a battery. I test

ran No2 on the Cedar Mountain Branch portable layout, and was gratified

to get 5 continuous hours of running light. I had a moderate

sized train (4 hoppers) tacked to her drawbar during the show over Thanksgiving

Weekend. I alternated her with Shay No6 and as a result the battery

never did go completely flat. All in all I'm very pleased with a

little teakettle that took less than 5 days to build!

|

|

|

|

|

|

|

|

This page and all contents Copyright Bart Salmons 2001/2002