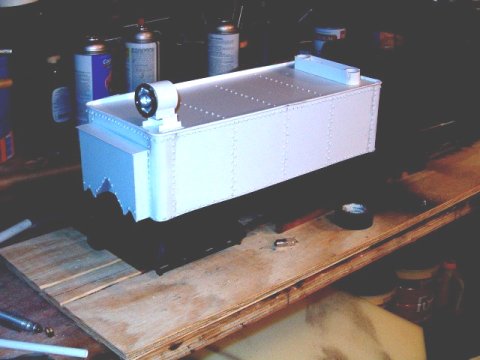

| The large tender is one of the

prime reasons for building a Class D 4 truck Shay, the tank itself is one

big cistern with a pair of Shay trucks underneath it. The rear truck

is an unpowered dummy while the No3 truck is powered giving No9 three motors

worth of GRUNT!!!

I built the tank frame for poplar timbers and covered these with a styrene overlay to simulate steel girders, exactly the same way the locomotive frame was done. End beams were added, and the floor of the tender was cut from 1/16" plexiglass. Figure 28. For the construction of

the tank itself, I once again drew on the genius of David "Fletch" Fletcher.

I used his ideer of water pipe corners to get the curved corners with a

plate of .040 styrene for the sub walls of the tender. Figure 29

.001 styrene wrapper was applied in much the same way prototypical sheetmetal

was used.

|

Fig 28 |

Fig 29 |

Fig 30 |

Fig 31 |

The rivet pattern was laid out

using standard constructon practices as a guide. The rivets themselves

are, you guessed it, the old reliable chunks of .080 rod. The tank

top is removable and sits on styrene angle. Figure 30 The water

fill will have an operating hatch to access the on off /sound control switches.

The sand box on the rear was fabricated from styrene, with the headlight

made from my standard plumbing cap, mini flashlight method (to be documented

in a future article). A rear ladder was soldered up from bras rod

and the whole shootin' match was pimed and pained with gloss black spraypaint.

Figure 31

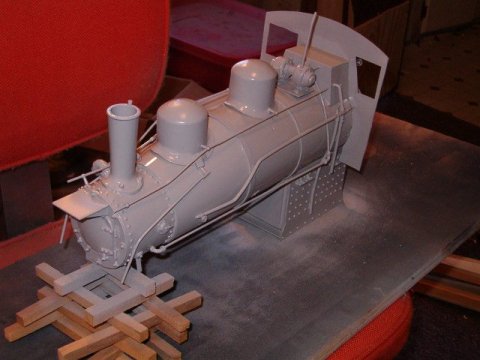

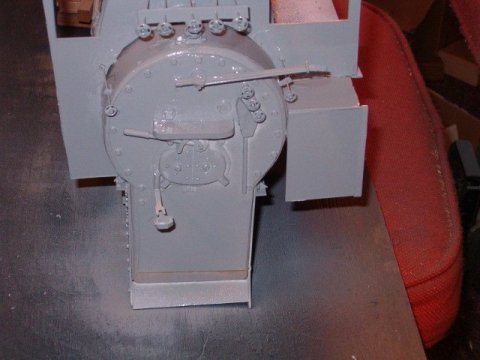

The rest of the boiler details were added and the whole boiler assembly primed. Figure 32 The basic cab controls were added as well. Figure 33 Since No9 is based on a Pacific Coast design, the turrent is enclosed in its own housing in front of the cab wall on the boiler, with only the actual handles extending to the backhead |

Fig 32 |

Fig 33 |