|

I have long admired the smallish

boxcabs used in industrial service around the country, the most famous

of which was probably the contractor loco used to relocate the D&RG

Narrow Gauge line for a dam construction project. My first

exposure to these little guys was probably the HOn3 version that Malcom

Furlow used in his series of articles building a project layout in HOn3.

Later a good friend of mine, Gary Buchanan built a set in 1:24 scale.

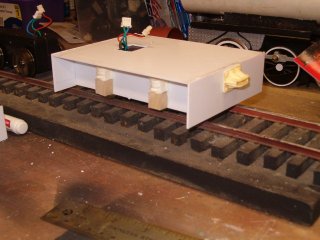

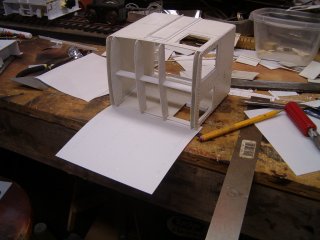

I had a Center Cab Switcher that had been stored in The Shop since the 2001 Cincinatti Garden Railroad Convention so I immedately set about dropping its power trucks off and constructing a chasis to set over them. Top plates were cut from .060 styrene and holes cut in them for power leads.(Fig2) |

Fig 1 |

Fig 2 |

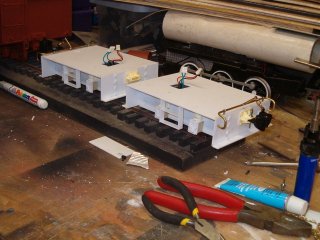

| Pilot and side plates were also cut form .060 to form a frame that dropped over the motor blocks. (Fig 3) For frame details I started by using some bolster castings I made to up size Bachmann trucks for 7/8 scale use to simulate spring suspension. Good ol fashioned wooden blocks represent the journal boxes. I used my standard Bachammn Knuckle adaptor casting on the pilot plates for mounting Bachmann Knuckles. (Fig 4) |

Fig 3 |

Fig 5 |

Fig 6 |

Journal covers were the next detail

undertaken. These were pretty much built up from scrap .040 styrene

with rivets punched from .020 styrene sheet and a chunk of styrene rod

for each. (Fig 5) Naturally 8 of them were made up in an evening

and applied to both chasis.

| Began adding some pilot details and steps to both chasis. the side steps were made up from pieces of .040 styrene I sliced off a sheet as well as the pilot steps.(Fig 7) The boltheads on the pilots were made from chunks of .040 styrene on my NWSL Chopper and glued in place. Bachmann Knuckles are applied and retained with my standard link pin, a pop rivet. By removing the spring in the Bachmann knuckle and trimming th flash on the drop pin, operating knuckles for 7/8 scale is possible. Using some brass chain, brass rod and some cotter pins, working cut rods are possible. (Fig 8) I applied working levers and couplers to both outside ends of the pair, but I think that I will use dummy equipment for the inside ends since the units will alwyas be used as an MU'd pair (Fig 9) |

Fig 7 |

Fig 8 |

Fig 9 |

Fig 10 |

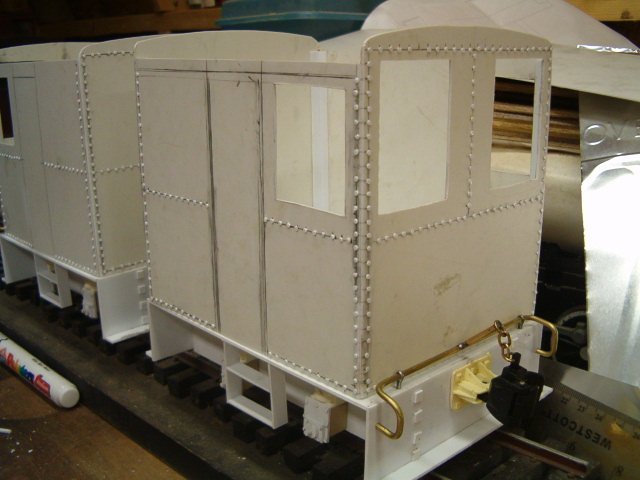

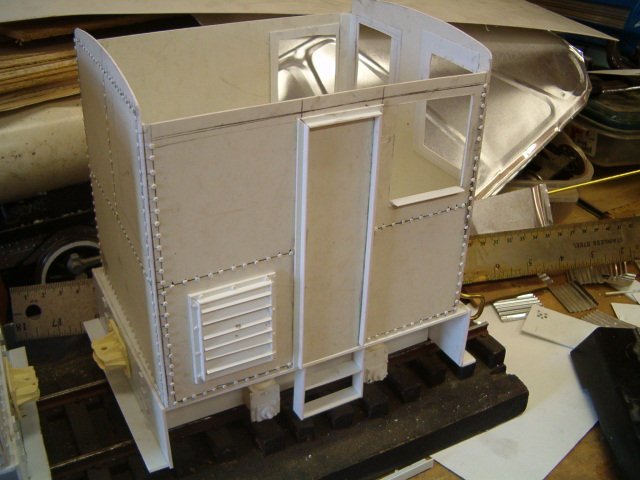

Walls for the carbody I laid

out on a CAD program and then printed out on cardstock to use as templates.

I only had to make two templates, omiting the windows when laying out one

end, and flipping the side so that the side window is at the same end of

the loco unit.

The sides were cut from .040 styrene sheet and are assembled with a piec of 1/4" styrene angle reinforcing each corner and keeping everyting square. |

Originally

I had intended to model a welded carbody like the prototype, since welding

was a provn technology by then, but decided this made for a plain and un

interesting model. After laying out the rivet pattern basically one

rivet every 3/16 of an inch I began appling the rivets using the McCowan

method. Basically thats each rivet was individually punched

from .020 styrene sheet with a 1/16 inch hole punch. Sounds

tedious, and it is, but it makes for a model with infinately more character.

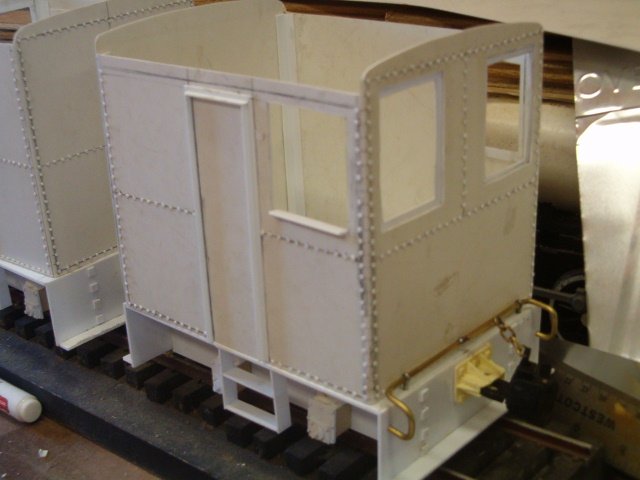

Moderate progress

before Real World matters interfered. Made a decision on which carbody

would be the lead unit, and left its window open with an armrest.

The other windows were fitted out with frames cut from .020 styrene.

The doors were framed with 1/8" styrene angle.

I had orginally

intended to put a radiator or air intake or something in the front of the

unit between the windows, but the width didn't allow me to do so.

I had thought of including air intakes on the roof to add some aditional

interest up there, but then thought it might get a bit crowded with a radiator

housing , stack, twin airtanks, and a headlight up there. My solution

was to add a bit more interest to the carbody by building an air intake

and mounting it to the operators side of each unit. I used a square

of .020 styrene that was leftover from the cutting out of the window frames

and framed it with 1/8" angle. The vanes of each vent were chopped

up on my NWSL Chopper, six were installed equally spaced within the frame.

Rivets of course were added by the tried and true McCowan Method.

Fig 14 |

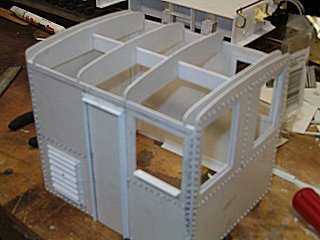

Today saw a roof added to both units. Sheet metal and compounds curves not withstanding this actually went a lot easier than I orginally suspected it would. First I cut a series of carlines from .040 styrene and connected them with a common ridgeline (Fig14) The carlines were notched to fit down on the sides of the carbody and to attach to the front and rear walls (Fig 15) with the framework in place I used a piece of typing paper to make a templat for cutting the .010 styrene for the actual sheet metal roof. with the appropriate shape formed I glued one edge of the roof in place and allowed it to dry. (Fig 16) |

Fig 15 |

Fig 16 |

| With the glue on the edge dried I was able to strectch the "skin" across the top of the carbody, glueing as I went and secure the other edge. Witht he help of some scrap wood and LOTS of rubber bands (the model builder's secret weapon) the sheet of styrene was held in place until it dried forming a convincining sheet metal roof. (Fig 17) |

Fig 17 |