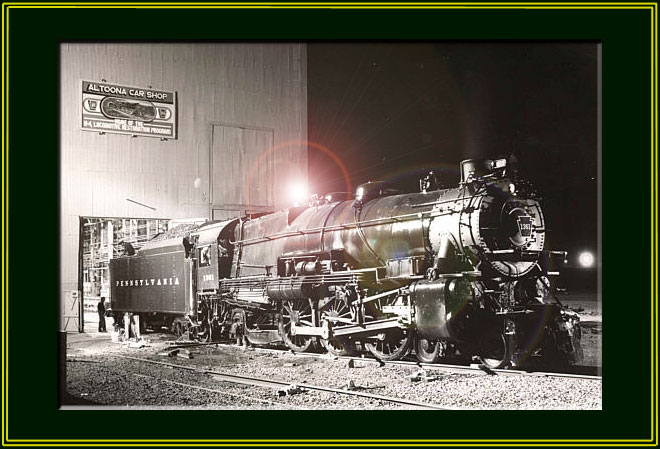

The PRR K-4s #1361

Steam Locomotive Restoration Project

Page 27

(This site is provided as a courtesy of the Altoona Railway Museum Club)

July 2006 K4 Update

These photographs were taken between January2006 and July 2006 by Charles Cantrell, 1361 Volunteer.

July 14, 2007 K4 Update

RAILROADERS MEMORIAL MUSEUM TEMPORARILY SUSPENDS K4 RESTORATION

ALTOONA, PA. -- The Railroaders Memorial Museum today announced that it has temporarily suspended daily restoration work on K4 1361 due to delays in expense reimbursement from the Commonwealth and concerns regarding the structural integrity of the K4's boiler. Daily shop work will cease within the next 10 days.

"We certainly regret having to make this decision. However, based on the information provided by our current employees and contractors, as well as our financial constraints, our only option is to drastically slow the pace of the K4 restoration project in order to properly complete the necessary engineering work on the boiler," said Scott Cessna, president and chief executive officer of the Railroaders Memorial Museum. "This will allow, once and for all, for the proper testing, repair, and documentation of the work necessary to bring the K4's boiler into compliance with Federal Railroad Administration regulations."

"There has been a change in reimbursement policy in Harrisburg as it relates to this project and we continue to work with the appropriate people there to obtain the reimbursement now properly due us in order to settle outstanding balances with our vendors. Those vendors who have already performed work on behalf of the project will be paid. This existing funding is secure and only the reimbursement method to obtain funds to pay for work already completed remains to be worked out with Harrisburg. Any level of additional funding over and above what we already have committed is tied to current budget negotiations in the Commonwealth," commented Cessna.

Cessna continued, "The Museum's Board of Directors has decided that when daily shop work resumes in earnest on PRR 1361, it will be done in Altoona at the new Harry Bennett Center, the Museum's roundhouse complex currently under construction. This will allow for more effective and efficient oversight of the project. It has been an insurmountable challenge to manage the project effectively while the restoration work was being performed in Scranton."

The Museum has completed the turntable installation and will shortly award the contract for the completion of the roundhouse itself.

During a recent examination of the boiler's roof sheet, the flat outer metal sheet on the roof of PRR 1361's Belpaire boiler, it was determined that portions of this sheet were too thin to allow the required safety factor for a boiler operated at pressure. The roof sheet must be in compliance with FRA regulations in order for the K4 to operate under its own power.

"I have the utmost respect for the current crew and contractors whose integrity demanded that they take the time to do the necessary calculations, examinations and measurements to catch this flaw before the boiler was completely closed and tubes/flues reinstalled." stated Cessna. "The Museum does not wish to rush into a fix simply to avoid further delays in an already long-delayed project. It is important, and required, that this be done properly, carefully, and within the safety guidelines established by the FRA."

April 14, 2010: "Official: Working K-4 Plans Derailed" (by William Kibler, bkibler@altoonamirror.com)

April 20, 2010: "Moving K-4 Steam Engine Still the Goal" (by William Kibler, bkibler@altoonamirror.com)

July 3, 2011: "K-4 restoration project moving full steam ahead" (by William Kibler, bkibler@altoonamirror.com; The Altoona Mirror)

It's hard not to be skeptical about the restoration of the Railroaders Memorial Museum's K-4 steam locomotive. Former board member Dick Charlesworth, who has observed the project for 15 years and longs for the iconic engine's return, is no longer even impatient, saying "It's at the point now, when it gets done, it gets done." If it ever gets done. But Larry Salone, executive director of the museum, said he's confident that after innumerable fits and starts on a project slated to take no more than two years, the K-4 is getting traction again. Troubles coupled to troubles have beset the project, including substandard work, poor management, numerous bypassed predictions for completion and a suspension of work in mid-2007, just before Salone took over. It was then that museum leaders decided to bring the unfinished locomotive in pieces from Steamtown National Historic Site, where the work had begun in 1996, back to Altoona. That, too, has happened in fits and starts. From the first, Salone has been cautious about raising hopes but has always insisted that the restoration is doable as "an engineering project." He's an engineer by profession. Now, things are happening, albeit slowly. The tender's almost done. It's back in Altoona, in the museum yard ready for painting after a recent a leak test. The main frame, drive and "steam chest" - which delivers steam to the cylinders - will be coming soon to Memorial Hall for tests. Except for a glitch, the move would have happened two weeks ago, but the huge truck and huge crane the museum needs to transport it are difficult to secure on the same day during the construction season, Salone said. When the main frame and its associated equipment arrives, workers will inspect components and double-check dimensions and paperwork. Previously, experts from The Strasburg Rail Road of Lancaster aligned the frame and workers from Steamtown bored out and "trued" up the steam chest, gauged and sized the pistons and bored the link rods and balanced and trued the wheels, Salone said. That work is likely OK. "It's not as screwed up as everybody said," Salone said. "I think we're in really, really good shape." The cab is here already in Memorial Hall. It needs some sheet metal work, upholstery and painting, he said. All three of those major components could be ready by the end of the year, "unless I found a catastrophic failure in the frame," Salone said. The boiler, however, is a different story. Previously, the Federal Railroad Administration approved part of the welding work on it, but someone trying to be helpful decided to dress it up with a grinder. That instantly negated the approval, Salone said. There may be other problems, too. The boiler is now at the East Broad Top Railroad shops in Orbisonia awaiting inspection this week by two qualified contractors the museum has hired. Museum employees will work with them to learn about the boiler and document the findings. A third contractor will comb through files still at Steamtown to learn "what's good and what's not," and what needs reverified, Salone said. Salone has met with FRA officials, who "made it very clear that boilers are not to be fooled with," he said. There will be X-rays and ultrasound testing for cracks and flaws and thickness tests for the boiler roof sheet. Once the inspectors identify any problems, the museum will hire an outside engineering firm to make repair "calculations." It will reduce those calculations to federal forms, take them to the agency, say "here's what we got," and propose a strategy for repair. "Hopefully, they'll like what we [propose]," Salone said. "It's like playing Jenga. It's a complicated little process." How labor-intensive, or how material-intensive, the work turns out to be will determine Salone's management of the work, because of limits on how to spend remaining grant money and the potential for in-kind donations. In any event, you can't rush it, he said. "Everybody wants it to be a race," he said. "We can't do it." The FRA has no plans to actually inspect the boiler "until the owner completes necessary repairs and requests a formal inspection," said an FRA spokesperson about the project. Salone understands the overall K-4 cynicism. People have said Strasburg Rail Road should have gotten the job, and in hindsight, it's probably true, given that firm's stellar reputation, Salone said. But there was no reason museum leaders should have thought the job would languish at Steamtown, which was new at the time, he said. People say the decision to send the locomotive there was politically motivated, but he can find no evidence of that, he said. When problems developed, the museum took over, but the project continued to flounder because the workers were too far away to manage effectively, he said. It was a time-and-materials arrangement, and while those are good for contractors, who can limit risk, they're not so good for management, because they're too open-ended - especially when management is using public money, he said. "[Then] you have the responsibility to go out and get firm pricing," he said. "You've got to have a budget, and you've got to know where the money is going." Still, he doesn't blame his predecessors. "That was not their skill set," he said. Nor does he blame Steamtown. Steamtown has been a good host during the locomotive's long residence there, he said. "They didn't force us out," he said, "in any way, shape or form." Nor does he believe the $2 million spent on the project so far was wasted. If it costs $500,000 more, the total will be reasonable, he said. Still, the work should go better in Altoona, he said. "Here, I can get a daily update, he said. Bob Yuill, who runs Historic Machinery Services of Springville, Ala., one of very few shops qualified to do the kind of boiler work the K-4 probably needs, is noncommittal on the future of the project. "I thought their ducks were in a row, and the contracts were going to be let" earlier this year, he said. But it always seems with the K-4 project that "everything seems to hinge [on] something else," he said. The quarter-roundhouse in the museum yard was the biggest "something else," he said. Work on the quarter-roundhouse should begin soon, and the building, which will house the K-4, should be ready in December. Yuill sympathizes with Salone. "[The K-4] is a very fluid-type project," he said. "He's got to kind of roll with the punches." It's hard to restore a locomotive whose original specifications were written a century ago, but whose current specs must take into account modern safety concerns, including from a steam explosion on the Gettysburg Railroad in 1995, which severely burned three tour operators, Charlesworth said. "Nobody wants to put their name on something unless they're absolutely sure everything's OK," he said. "If [another one] blows up, you will have pieces of metal a mile away." People have suggested the museum should give the K-4 to some organization that could get it done, Salone said. He doesn't want to hear it. "It's the museum's project," he said. When and if it finally gets done, it could be the museum's "savior," Charlesworth said It'll bring tourists and generate lots of revenue, museum board member Greg Saylor said. An excursion weekend would look like a Penn State football game, Charlesworth said. He recalls the initial excursion in 1987, before an axle failed, setting off the chain of events that is still playing out. "It was a nightmare if you were a truck driver going up [Route] 220," Charlesworth said. "Bumper-to-bumper traffic, people everywhere." "That's why it needs to run [again]," he added. "I can't wait to ride in that puppy," Salone said. "But let's make sure it doesn't blow up."

Aug 7, 2016: "Believers keep hopes alive of K-4 under steam" (by William Kibler, bkibler@altoonamirror.com; The Altoona Mirror)

In the 20 years since the Railroaders Memorial Museum launched its effort to restore the Altoona-built K-4 steam locomotive 1361 to operating condition, officials have repeatedly predicted dates and costs for completion. Those have all blown away like smoke on the mountain, and the locomotive - despite the expenditure of $3.8 million in government funding - remains in pieces. Last week, asked for a project update, museum Board President Andy Mulhollen declined to make new predictions but insisted - despite past errors, supervisory dismissals, work that needed redone and talk about settling for a static display - the museum intends to get the big machine running again. A "knowledgeable source," who didn't want to be named, said a small group of people "within the industry who have an interest in seeing the project completed" has forged an understanding with the museum giving the group management control of the planned restoration - although the museum remains the ultimate owner of the K-4. That group offers hope for the project, given the intentions and capabilities of its members. "I believe we have people lined up who are serious people and who will make the (financial) commitment, once they know what the commitment has to be," said the source, who is peripherally involved with the group. There are no plans to ask for any more government money, according to Mulhollen and the source. "We think the public has been burnt with this (restoration)," the source said. The group is aiming for redemption. If this can be done, it buries a lot of embarrassment," the source said. For the past two years, a small group of volunteers, all craft employees at the Juniata Locomotive Shop of Norfolk Southern, have been sustaining the project, working one night a week at most, according to Mulhollen and the group's leader, pipefitter Mike Reindl. The group has helped inventory and organize the parts, all of which are now under roof at the museum, and have been working at various tasks within their capabilities and the limits of the equipment and space at their disposal in the museum's quarter-roundhouse and Memorial Hall. "We're plodding along," Mulhollen said.

Under a 'black cloud'

The group is determined to keep the project's "spirit" alive, said Reindl, a 32-year-old, fifth-generation railroader whose grandfather - "my buddy" - taught him about steam engines with the help of books that Reindl read sitting on the older man's lap. The volunteers love the work, which continues despite the "negativity" that has surrounded the project for years, Reindl said. The project may be under "a black cloud," but it has included plenty of investment "in the right places" to produce critical components that now await reassembly, Reindl said. Components have been refurbished or recreated by employees of the project at Steamtown in Scranton - in the early years of the restoration phase - or by subcontractors, and they're stored in crates, on skids or on the floor, depending on their size. The pieces include the drive wheels, tall as a man, installed on new axles and with new steel "tires" to ride the rails.

The parts include the "cross-compound air pump," tucked away in its own box.

There are also the components of the staybolts designed to hold the inside and outside walls of the firebox together - and a specified distance apart - while providing seals that keep the critical cooling water that goes in between those walls. The volunteers are doing good work, Mulhollen said. Still, at some point, the project will need an infusion of money, certified specialists working by contract and a professional project manager, Reindl said.

Boiler key issue

The chief obstacle to the restoration has always been the boiler, because of the risk of catastrophic failure, due to the high pressure of the steam it produces. Much work has been done over the years to the old boiler, which includes the firebox, barrel and smoke box, and it now meets the "middle-of-the-road" standards in place when the Pennsylvania Railroad workers built the K-4 in 1918, Reindl said. But it doesn't meet modern safety standards and lacks the necessary OK of the Federal Railroad Administration, which last ruled on it 10 or 11 years ago, disapproving repairs that had been made, according to FRA spokeswoman Desiree French. Concerned about the boiler's "old metallurgy" and the stresses it underwent in PRR service, the group that has taken an interest in the project hired a consultant to help determine whether it makes sense to order additional repairs or to commission construction of a new boiler. The group would prefer a new boiler to minimize liability - especially liability for Norfolk Southern, whose lines could be a gateway to the rest of the state and its many short-line routes, so the K-4 could pull excursions for education and tourism, according to the source. But those excursions can't happen without the "cooperation and support" of Norfolk Southern.

The group would be willing to pay more for the new boiler, provided it's not too much more, according to the source. "We're very conscious of the weight on the scales between liability and saving a few bucks," the source said. "We know the existing boiler will never fully meet ASME (American Society of Mechanical Engineers) requirements for (the K-4's designed) working pressure." Those ASME standards are higher than FRA standards for locomotive boilers. The operating pressure for the K-4 is 205 pounds per square inch, according to Mulhollen. Even the current FRA standards require the boiler to be designed to withstand "multiples" of that operating pressure, according to Mulhollen. In its current state, with no further repairs, the boiler could operate at 185 psi under FRA standards, according to Reindl.

That would allow the locomotive to run at 40 mph, which is the limit Norfolk Southern placed on steam engines operating on its lines previously, according to Reindl. But Reindl figures that with the locomotive apart and under reconstruction, the museum shouldn't settle for those limitations. Likewise, the group doesn't want to operate at 185 pounds, because that would be "a tacit admission that it's not what it's supposed to be" - an admission that could be detrimental in court, the source said. The current boiler falls short of the current FRA standards in not having a thick-enough outer roof sheet for the firebox, Reindl said. Replacing that under a certified boiler expert would allow the K-4 to run at 205 psi, Reindl said. But the group wouldn't necessarily be satisfied with that.

Boiler not original

It favors a new boiler, because the group members are looking "through the eyes of a risk manager for the railroad," the source said. The group also favors a new boiler despite the already-large investment in boiler repairs. Between 60 and 70 percent of the boiler - as with the K-4 overall - is new material, Reindl estimated. That includes the entire smoke box and the bottom "mud ring," inner and outer "door sheets" and outer side sheets of the firebox, he said. There have also been tests to verify the soundness of the barrel, he said. All that doesn't matter, according to the source. Those are sunk costs, he indicated. The group's "rational" approach is to assess the situation on its merits, the source said. A new boiler would ensure trouble-free operation for many years, Mulhollen said.

Asked whether installing a new boiler would diminish the K-4's authenticity, Mulhollen said maybe, if the museum were planning to make the K-4 a static display, but maybe not - given the plans to run it. The boiler that came with the locomotive the museum inherited after it went out of revenue service in 1956 wasn't even installed until the 1930s or 1940s, anyway, Mulhollen said. That boiler was like many other components not on the original machine 98 years ago, he said.

During its history, the K-4 devolved into a conglomeration of parts from different periods, installed when others wore out, according to Mulhollen and Reindl. Such turnover was in keeping with the PRR's practice of standardization, which it pioneered, and which enabled it to interchange parts within and sometimes between classes of locomotives, according to Mulhollen, Reindl and the source. "They were not trying to preserve history," Mulhollen said of PRR decision makers. "They were trying to run a railroad." And because the end of the line for the K-4 was also the end of the line for steam power on the railroad, the K-4 was especially "tired" at the end, as the PRR minimized investment in the doomed technology, Reindl said. To illustrate, he pointed to a smoke baffle, a non-critical piece of flat steel about a yard long and a foot high, with multiple cuts that look to have been made with a burning torch, carelessly. Those jagged edges contrast with the precise outlines of a replacement baffle fabricated by the volunteer crew.

'Turns men into kids'

The K-4 represents the best of Altoona, when so many worked for the railroad, building machines like the K-4 virtually from scratch - casting, forging and welding iron and steel, fashioning copper, bronze and brass; making bolts and lubricants, testing individual items like lightbulbs and assembling and testing the completed engines, Reindl said. The scale of the K-4 is intimidating - the size of the components, their thickness and weight, their number and complexity and the science behind the operations they perform. There's pride to be taken in that, said Reindl, who works with three machinists and an electrician. People should realize the opportunity represented by the K-4, he said. "It's real, and it's here," Reindl said. "It turns old men into kids," said former state Rep. Rick Geist, who was involved as early as 1985 in the effort to get the K-4 running again. Geist and Reindl both recalled the crowds that came to see the K-4 during the excursions run in the late 1980s, after quick-and-dirty repairs got the locomotive running again before a catastrophic failure shut it down. That same excitement would recur, they said, if and when the K-4 is brought back into operation. "There have been a lot of bumps," Mulhollen said. "But we haven't given up."

Mirror Staff Writer William Kibler is at 949-7038.

Thank you for viewing the K-4 restoration webpages. Unfortunately, I don't have any further information (post July 2011) on the effort. Information will be posted as it becomes available. For further inquiries, please contact the Altoona Railroaders Memorial Museum. If you have photographs and narratives of the 2011-Present effort, feel free to contact me to have them included on this site!

For further information see the "Friends fo the PRR K4 1361" Facebook Page.