|

Home

The Railway Organisation

Plant Maintenance

|

Air Conditioning (A/C)

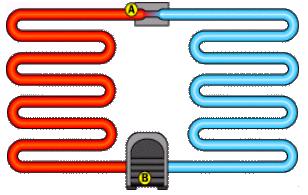

Wherever some plant or electrical equipment is housed, there usually has to be some air conditioning present in order to maintain air temperature. This prevents the equipment from either overheating or overcooling. Some of the air conditioning units are quite large and complicated. As mentioned, I went out to see the 650V UPS at Church Fenton when it was commissioned (12th Jan 2001). As the UPS is contained within a building, a new air conditioning system was installed. An air conditioner acts in a similar way to a refrigerator. Air conditioning can easily be described and is represented in Fig. 7.

The compressor compresses cool Freon gas, causing it to become hot, high-pressure freon

gas (red in the diagram). This hot gas runs through a set of coils so it can dissipate

its heat, and it condenses into a liquid in the process. The freon liquid runs through an

expansion value, and in the process it evaporates to become cold, low-pressure freon gas

(light blue in the diagram). This cold gas runs through a set of coils that allow the gas

to absorb heat and cool down the air inside the building.

Mixed in with the Freon is a small amount of lightweight oil. This oil lubricates the

compressor.

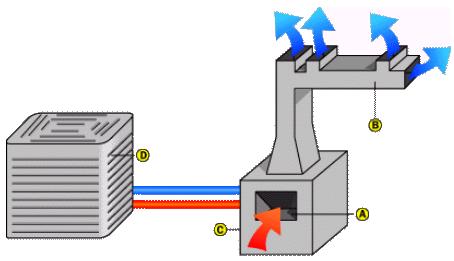

Split-system Air Conditioners

A split-system air conditioner splits the hot side from the cold side of the system,

like this:

The cold side, consisting of the expansion valve and the cold coil, is generally placed

into a furnace or some other air handler. The air handler blows air through the coil and

routes the air throughout the building using a series of ducts. The hot side, known as the

condensing unit, lives outside the building.

It consists on a long spiral coil shaped like a cylinder. Inside the coil is a fan to

blow air through the coil along with a weather-resistant compressor and some control logic.

This approach has evolved because it is low cost and also because it normally results in

reduced noise. Besides the fact that the hot and cold sides are split apart and the capacity

is higher (making the coils and compressor larger), there is no difference between a

split-system and a compact one as described above.

The system at Church Fenton is of the split system kind. The units that blow air into the

room can be seen below.

All SSP's contain important equipment for the running of the railways. There are two sets

of air conditioning units at the Church Fenton UPS room. This is in case one unit fails.

If, for instance, there was only one A/C unit, and this failed, there would be a chance

that the UPS would not work due to overheating. If this were the case, and the REB supply

failed, the 10 - 12 second signalling blip would be experienced.

All this seems very unlikely, and therefore one has to wonder if it really is worth investing

in two sets of air conditioning. The key factor to remember, however, is that the aim is to

keep the signals powered at all times. Investing in all of this equipment results in minimum

risk of a signalling failure.

|