BUFFALO CREEK #43

ALCO HH660

Updates 2013

February 2013

|

|

|

|

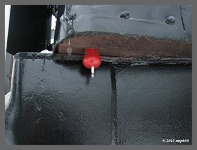

| On every locomotive you will find an "Emergency Fuel Cut Off" handle somewhere at frame level. Someone removed #43's and so we found a new handle and added new cable to the Fuel Pump cut off valve. The simple pulley system works great! |

| Just found video of #43 working at EMPAK Chemical in Fitzgerald, GA. in 1998 as RELCO #606. Hopefully it won't be too long before we can make our own action video's of this old girl in action. Thank you to "fmnut" for capturing this historic video |

April 2013

|

|

|

May 2013

| Since we had the long hose out we refilled the cooling system with 285 gallons of fresh water and 5 pounds of water treatment. Bob M. made a great long handled brush which cleaned out the water glass in the cab. All of the replacement wood on the cab ceiling has been installed. We are getting close to priming the interior so the final interior paint can be applied. |

June 2013

| herd was a Jordan Spreader built in 1946. Scot Lawrence has these engines all well documented on his WebSite, "ALCO Locomotives of New York State" Please understand that this is a full time railroad and TRESPASSING is not allowed! Take all the photo's you want from Scott Street but please stay off the tracks. The Society has Waivers of Liability and takes all steps necessary to meet FRA Safety Standards. |

| All the wainscott on the ceiling has been scraped and sanded to remove the flaking ancient varnish and ALCO Green paint. We can now prime everything before the finish coats of paint go on. |

July 2013

|

|

September 2013

November 2013

| The WNYRHS greatly appreiciates all the generous donations to this project to date. However, we could still use your help! All Donations to the WNYRHS, Inc. are Tax-Deductable! If you would like to mail in a donation, send it to WNYRHS Inc., PO Box 416, Buffalo, New York 14231-0416 or |

| Click the PayPal Button to make a Secure Electronic Donation. THANK YOU! |

Web Site Hosting by TRAIN WEB

The WNYRHS, Inc. P.O. Box 416, Buffalo, NY. 14231-0416 is an independent organization and has no affiliation with any other local or national group.

The Society is a fully qualified organization under 501 (C) (3) of the Internal Revenue Code and all donations to the Society are tax deductible.

©Copyright 1999 , WNYRHS Inc. all rights reserved