BUFFALO CREEK #43

ALCO HH660

Updates 2015

by Scott H.

January - June 2015

| You all know how brutal a winter we had so the work in Hamburg, New York, got off to a very slow start. Last year we were able to finish the work on the interior of the cab of Buffalo Creek #43 using a propane heater. By fall we moved onto working on the prime mover which is outside. |

| On our next outing we borrowed an electric oil pump from the Buffalo Southern Railroad to "pre-lube" the engine. The crankshaft had not been turned since 2009 so it needed to be done again. |

| The flywheel cover was removed to access to the holes in the flywheel into which a large round bar is inserted and you lean into it. It took two of us to get the first 1/10 of a turn going but after that everything moved freely! |

| Jim was able to buy a new filter right off the shelf at NAPA. The fuel tank was a concern due to the condition of the top of the tank which is also the sub-floor of the locomotive. Last year we scaled, primed and greased the top of the tank to prevent any further decay. We drained almost a quart of water from the fuel sump before clean diesel fuel came out. |

|

Bob M. took the 72volt DC fuel pump motor to Dell Electric to have it tested. In the meantime, we used a cordless drill to turn the fuel pump and prime the line up to the secondary filter |  |

July 2015

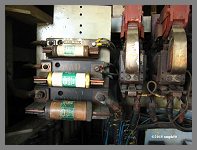

| We had another beautiful day on July 23rd to work on the electrical system. Anxious to check out our battery cables, we moved our 36 volt battery pack out to the fireman's side walkway. The battery compartment cover was removed and the batteries connected with jumper cables. Using a VOM, we were pleased to see we had 36.8 volts at the battery knife switch. After cleaning the contacts of the fuses and switch, we delicately closed the switch and then opened it when the sparks flew! After removing all three main fuses (compressor, radiator fan and auxiliary generator) we found the problem in the aux generator circuit. With that fuse removed and the battery switch closed, we had 36 volts to the control stand which gave us power to the fuel pump, lights and radiator fan! |

| We found out that the Forward/Reverse control handle on the control stand was in the full forward position. This was causing the big EF & GF relays to try and close when the battery switch was closed and the field coils on the starter/aux generator were being energized. This was way too much current for our 36 volt battery pack to supply and is what caused the electrical arc. |

|

|

|

|

|

August 2015

| On the 27th we finished many of the details necessary to ensure everything would be ready for our "prestart" inspection by the Buffalo Southern. Bob M. worked on wiring details while Rick B. and I pulled the six valve covers to inspect and prelube the rocker arms. All six valve chests looked clean and had no issues. We also sealed the crankcase covers and barring cover with silicone that were removed when we turned the engine over. |

|

|

|

|

September 2015

By Scott MP Hawbaker

October 2015

By Scott MP Hawbaker

November 2015

December 2015

| The WNYRHS greatly appreiciates all the generous donations to this project to date. However, we could still use your help! All Donations to the WNYRHS, Inc. are Tax-Deductable! If you would like to mail in a donation, send it to WNYRHS Inc., PO Box 416, Buffalo, New York 14231-0416 or |

| Click the PayPal Button to make a Secure Electronic Donation. THANK YOU! |

Web Site Hosting by TRAIN WEB

The WNYRHS, Inc. P.O. Box 416, Buffalo, NY. 14231-0416 is an independent organization and has no affiliation with any other local or national group.

The Society is a fully qualified organization under 501 (C) (3) of the Internal Revenue Code and all donations to the Society are tax deductible.

©Copyright 1999 , WNYRHS Inc. all rights reserved