|

|

ACL Class R-1 4-8-4's

the

"Eighteen-hundreds"

|

(dropdown menu)

updated 22 February 2022

Specifications

|

|

| GENERAL

DATA |

| 28.

HEATING SURFACE, SUPERHEATER |

1,425

SQ. FT. |

|

| 1.

CYLINDERS: DIA. X STROKE |

27"

x 30" |

|

| 29.

HEATING SURFACE, EQUIVALENT

TOTAL |

6,891

SQ. FT. |

|

|

|

| 30.

GRATES, AREA |

97.7

SQ. FT. |

|

| 3.

VALVES, SIZE & KIND |

12"

PISTON |

|

|

| 4.

VALVE, MAXIMUM TRAVEL |

7

1/2" |

|

|

| 5.

VALVES, STEAM LAP |

1

3/8" |

|

AIR

BRAKE |

| 6.

VALVES, EXHAUST CLEARANCE |

1/4" |

|

| 33.

SCHEDULE |

W.A.B.

CO. TYPE 8-ET |

|

| 7.

VALVES, LEAD IN FULL GEAR |

1/4" |

|

| 34.

BRAKE PWR |

60%

DRVRS & 45% B. TRUCK @

50 LBS PRESSURE |

|

| 8.

VALVES, CUT-OFF IN FULL GEAR |

85% |

|

| 35.

PUMPS |

2-8

1/2" CROSS COMPOUND |

|

| 9.

RATED TRACTIVE POWER |

63,900

LBS. |

|

TENDER |

| 10.

RATIO OF ADHESION (WT. ON

DRIVERS/TRACTICE POWER) 4.12 |

|

| 11.

SHARPEST CURVE |

16

DEGREES WITH 1/2" TRACK

SPREAD |

|

| 37.

DRAFT GEAR |

MINER

A-5-XB |

|

| WEIGHT |

| 38.

BRAKE SCHEDULE |

W.A.B.

CO. TYPE 8-ET |

|

| 12.

LEADING TRUCK |

89,343

LBS. |

|

| 39.

BRAKE PWR |

100%

@50LB. PR. OF LT. WT. TNDR

(186,200 LBS.) |

|

| 13.

TOTAL DRIVERS |

263,127

LBS. |

|

| 40.

TRUCK, TYPE |

8

WHEEL RIGID FRAME, CAST

STEEL |

|

| 14.

TRAILER TRUCK |

107,800

LBS. |

|

MISCELLANEOUS |

| 15.

TOTAL ENGINE |

460,270

LBS. |

|

| 41.

INJECTOR |

NATHAN

TYPE HP |

|

| 16.

FRONT TENDER TRUCK |

222,450

LBS. |

|

| 42.

LUBRICATORS |

2

NATHAN MECH. DV-7 |

|

| 17.

REAR TENDER TRUCK |

213,050

LBS. |

|

| 43.

POWER REVERSE |

BALDWIN

TYPE "C" |

|

| 18.

TOTAL TENDER |

435,500

LBS. |

|

| 44.

DRIVING BOXES |

TIMKEN

ROLLER BEARINGS |

|

| 19.

TOTAL ENGINE & TENDER |

895,770

LBS. |

|

| 45.

FIRE DOOR |

FRANKLIN

BUTTERFLY TYPE No

8 |

|

| BOILER |

| 46.

SUPERHEATER |

ELESCO

TYPE "A" |

|

| 20.

WORKING PRESSURE, MAX. |

275

LBS. |

|

| 47.

HEADLIGHT |

GOLDEN

GLOW |

|

| 21.

FIREBOX, LENGTH X WIDTH |

138"

x 102" |

|

|

| 22.

TUBES, No,

O.D. & GA. |

198~2

1/4" ~No

11 B.W.G. |

|

| 49.

TRAIN CONTROL |

GENERAL

RY. SIGNAL |

|

| 23.

FLUES, No,

O.D. & GA. |

58

~5 1/2" ~No

8 B.W.G. |

|

| 50.

AIR PUMP LUBRICATOR |

WEST'G.

MECH. TYPE F-1 |

|

| 24.

TUBES & FLUES, LENGTH

(OUT. TO OUT. OF TUBE

SHEETS) |

252" |

|

| 51.

FEED WATER HEATER |

WORTHINGTON

OPEN TYPE 5 1/2 SA |

|

| 25.

HEATING SURF., TUBES &

FLUES |

4,185

SQ. FT. |

|

|

| 26.

HEATING SURF.,

FIREBOX,SYPHONS,

COMB.CHAMBER |

568

SQ. FT. |

|

| 53.

SPEED RECORDER |

VALVE

PILOT |

|

| 27.

HEATING SURFACE, TOTAL |

4,753

SQ. FT. |

|

|

General data on the R-1 from the ACL

The R-1's were the only "modern"

steam locomotives owned by the ACL, and featured cast

bed frames with cylinders and many accessories cast

integrally, cast pilots with drop-type couplers, ASF

roller bearings on leading axles, Timken roller

bearings on the driving axles with lateral motion

devices on the front axle, Baldwin disk drivers, 275

PSIG boilers, Type "A" superheaters, Worthington SA

feedwater heaters, front-end throttles, large

fireboxes with combustion chambers and equipped with

four thermic syphons, Elesco centrifugal steam

separators, extensive mechanical lubrication, and

massive 8-axle tenders. The engines featured jacketed

smokeboxes and were painted in a sharp two-tone

metallic gray/black paint scheme with silver striping,

lettering and driver tires. The ACL herald on the

tender was a separate embossed sheet metal disk which

was attached to the tender providing a dramatic change

from earlier engines which merely had "Atlantic Coast

Line" lettered on the tender. The detailed procedure

for painting the engines can be downloaded here: Baldwin

Locomotive Works Painting, Lettering and Numbering

Specification for the R-1 Locomotives

The R-1's were

overhauled at the ACL shops in Tampa, Florida, as

they were too large for the road's backshops in

Rocky Mount, North Carolina. Tampa is southwest of

the ACL's Jacksonville to Richmond mainline, which

required the locomotives to stray from their usual

operating territory when heavy repairs were

required. When a locomotive was sent to Tampa for

overhaul, it was used on a freight train into Tampa.

The R-1's were limited to 40 MPH over most of this

line south of Jacksonville, and even slower over

some bridges, so this must have been a headache for

the railway.

An interesting

feature on the R-1's which I have not seen on other

modern steam locomotives was the omission of wedges

from the frame pedestal openings. Wedges allowed the

gaps between the pedestal openings and the axle

boxes (which contained the roller bearings) to be

adjusted for proper clearance. Earlier versions of

wedges had to be manually adjusted by machinists

when the engines were brought in for maintenance.

Turning a bolt located below the wedge, raised or

lowered the wedge, reducing or increasing the

clearance between the frame opening and the axle

box. Around 1940, Franklin introduced self-adjusting

wedges, which included an adjustable spring to shift

the wedges to maintain proper axlebox clearance over

long periods without intervention by shop personnel.

The pedestal openings on the R-1's had to be

adjusted by inserting shims of the appropriate

thickness between the shoes and the frame. At

overhaul the axle openings in the frame would have

to be trued by grinding or welding up and then

grinding. Perhaps Baldwin or the ACL believed wedges

would no longer be needed with cast bed frames and

that adjustments would rarely be required, but this

was apparently not the case.

Interestingly,

according to former ACL machinist Jerald McGowan,

the main driving axles required replacement at every

overhaul as machinists invariably found a tiny crack

in the axle at the inner edge of the wheel hubs. It

was such a common problem that partially finished

replacement main axles were maintained in stock at

Tampa so they'd be available when the engines were

overhauled.

Interestingly, the drivers were not

keyed to the axles but relied on the press fit to

keep them quartered.

Few changes were made

to the R-1's during their careers. Provisions were

made in the original design to allow trailing truck

boosters to be fitted, but this was never done.

Photographs show that within the first couple of

years of service, the original whistles, mounted at

the steam dome and fed with saturated steam, were

replaced with larger whistles mounted on the

fireman's side of the boiler just behind the stack

on the superheater header, where they were fed with

superheated steam (see photo below). Headlights seem

to have been changed or modified on some if not all

of the locomotives as well. In the 1940's,

some or all of the locomotives were equipped with

Valve Pilot devices, which gave guidance to the

engineer operating a locomotive on the optimum valve

cutoff setting ensuring maximum operating efficiency

and fuel economy. Finally, locomotives 1800, 1801,

1806, 1807, 1808, and 1809 were fitted with Timken

light-weight pistons, piston rods, crossheads, and

new tapered main rods with roller bearing wrist pins

(see photos below). These components greatly

reduced the mass of the reciprocating parts which

improved the R-1's running gear balance even

further. At least some locomotives had some drivers

replaced with later versions of the Baldwin disk

drivers. A comparison photo of these is

provided as well.

ACL R-1 Details of

Interest

The photos below point out some minor

changes made to the R-1's during their service on the

ACL.

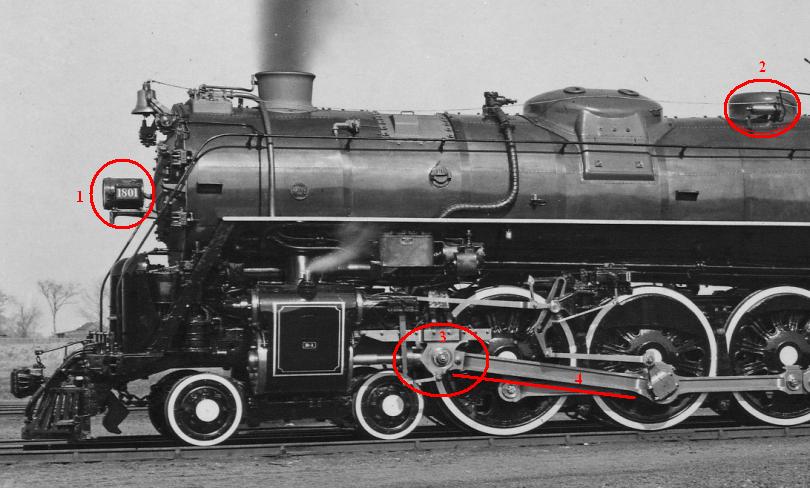

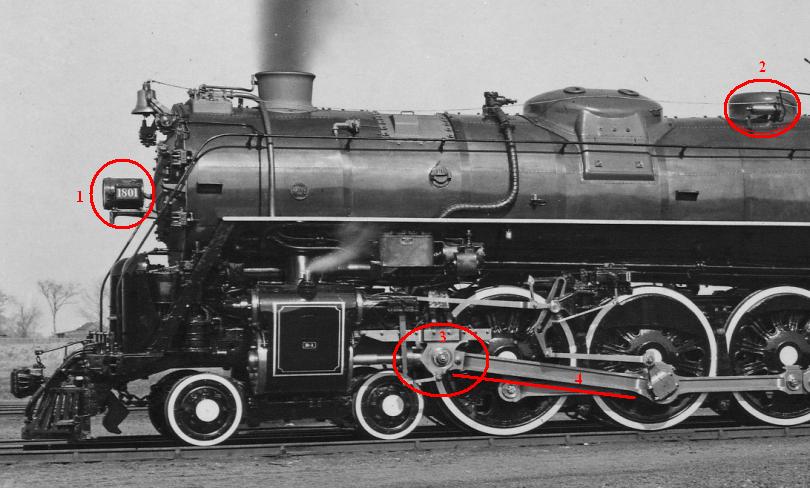

Builder's Photo

(above) of R-1 showing (1) original headlight, (2)

original whistle fed with saturated steam from the

steam dome, (3) heavy, one-piece forged crosshead

and (4) heavy, non-tapered main rods. This photo

also shows the ASF wheelsets on the lead truck,

indicated by the large hubs with bolts around the

perimeter, which were an interesting development

of the 1930's. These wheelsets included both

roller bearings and conventional journal

bearings on each axle. Apparently the purpose of

this arrangement was to allay the fears of

conservative railway managers, some of who did not

trust the relatively new roller bearings.

The friction bearings on the ASF wheelsets could

serve as a back-up if the roller bearings should

fail. Other notable locomotives equipped with

these axles were the massive 2-8-8-4's of the

Duluth, Missabe, and Iron Range Railway in

Minnesota. These axles, which were undoubtedly

considerably more expensive than a conventional

axle, were used for a relatively short time on new

locomotives, as railroads' experience proved the

reliability of roller bearings.

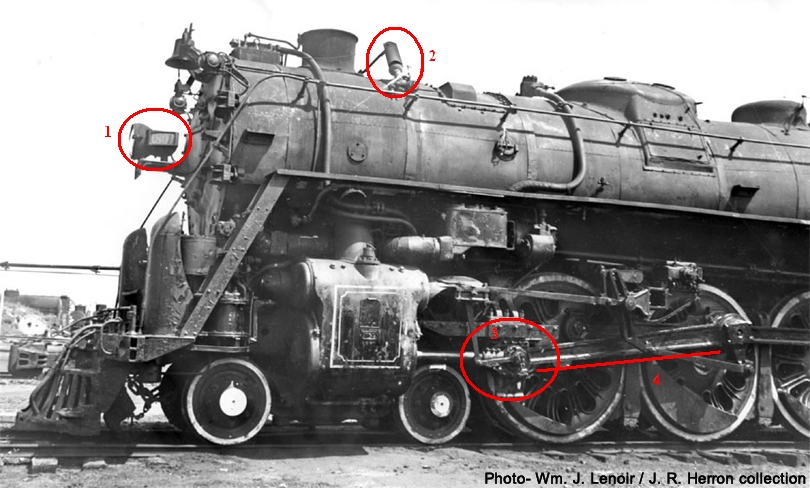

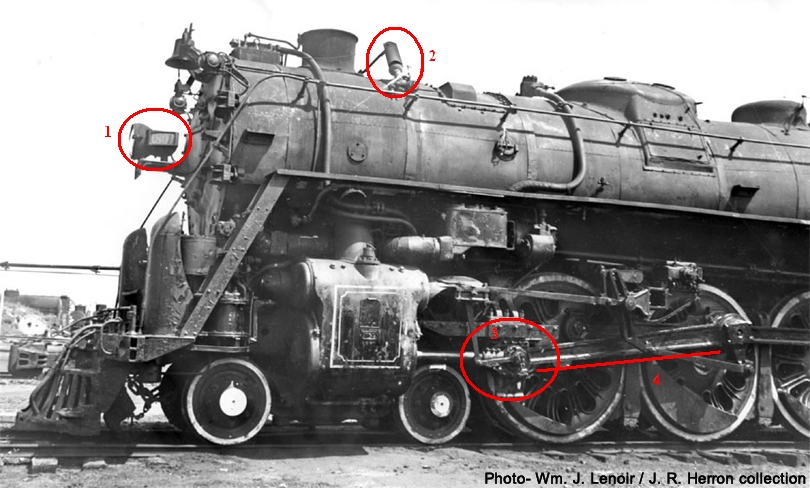

Late photo

(above) of ACL R-1 showing (1) what appears to be

a different headlight, (2) larger whistle fed with

superheated steam from the superheater header, (3)

Timken light-weight crosshead (not seen are Timken

light-weight piston and piston rod), and (4)

light-weight, tapered main rod with roller bearing

wrist pin. This photo unfortunately also shows the

dirty condition somewhat typical of most ACL

steam, especially near the end of steam on the

railway.

It appears the

original whistles were the standard Baldwin

Locomotive Works whistle, which was usually a

3-chime whistle. The later whistles which were

installed shortly after the locomotives were

placed in service were likely the Atlantic Coast

Line's own 6-chime whistles. You can hear one of

these whistles on this short clip from the 1952

movie "the Greatest Show on Earth", where a much

smaller ACL P-3 Pacific pulls a circus

train: Atlantic

Coast Line P-3 Whistle

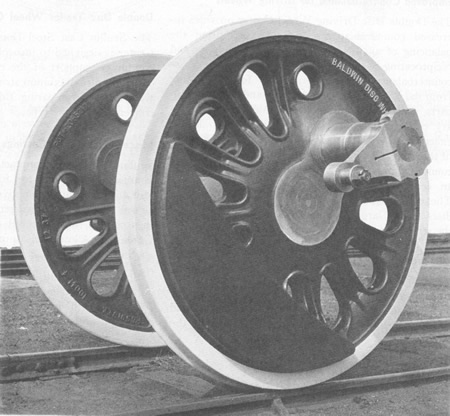

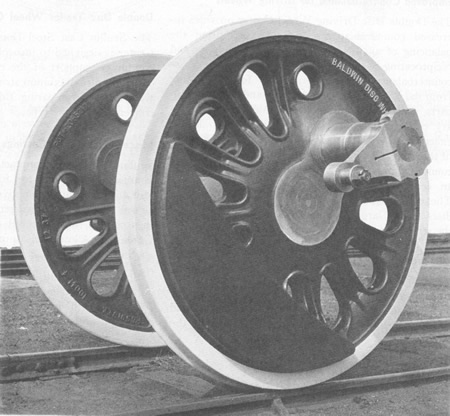

This photo shows

a brand-new set of Baldwin disk drivers awaiting

installation on a new steam locomotive, possibly

an ACL R-1. These wheels were of hollow

cross-section, similar to the better known Boxpok

drivers used on many modern steam locomotives.

Many contemporary Santa Fe locomotives were also

equipped with Baldwin disk drivers, and many other

locomotives on a variety of railways were retrofit

with these wheels during updates in the 1930's and

1940's. The ACL installed Baldwin disk main

drivers on many of their steam locomotives in the

1930's and 1940's including the P-5 Pacifics and

Q-1 2-10-2's. The hollow cross-section made the

wheels stronger and allowed more room for

counterbalancing material.

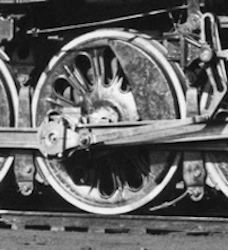

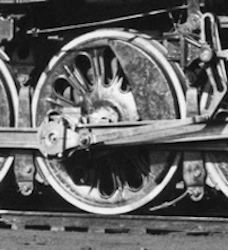

Baldwin later

somewhat simplified the design of these wheels by

omitting the raised ribs between the openings and

photos show that at least some R-1's wound up with

the newer version of the wheels. The two photos

above show the main drivers on R-1 no. 1808; the

left photo shows the original style and the right

photo shows the newer version of the wheels.

The other drivers were not changed on this

locomotive. Sante Fe 4-6-4 no. 3463, currently on

display in Topeka, Kansas also sports two

different versions of Baldwin disk drivers,

indicating some drivers were replaced over the

locomotive's life, so this may have been a common

issue. The reason for the change is not known, but

perhaps there were issues with at least some of

the wheels cracking after many miles of use.

Another

interesting feature of the R-1's were the Atlantic

Coast Line heralds on the tender, which were

embossed 45 inch diameter plates bolted to the

sides of the tender rather than just a logo

painted directly on the tender sides. The plates

were provided by the Allen-Morrison Sign Company

of Lynchburg, Virginia. Allen-Morrison was famous

for making many of the now-collectible Coca-Cola

signs, as well as other signs used in advertising.

The builder's drawings for the locomotives show

that rivets were omitted in the area of the tender

where the heralds were installed. Welding was used

to secure the internal braces to the exterior

sheets in this area. The rivet-free area can be

seen on the photo of N&W 2084 with the herald

removed on the Disposition page.

The

R-1's were well-designed steam locomotives and

were nearly state-of-the-art for 1938, lacking

only roller bearing axles on the trailing truck

and tender axles. Their large fireboxes with

combustion chambers and 4 Nicholson Thermic

Syphons were among the largest in heating surface

area of any 4-8-4 and undoubtedly made them

prodigious steamers. One curious feature is

Baldwin's use of relatively small piston valves

for such large engines which seems to have been

part of Baldwin's design philosophy at the time.

The R-1's had only 12 inch diameter piston valves

whereas even the ACL's much smaller and older

Class P-5 Pacifics had 14 inch valves. The R-1's

also had somewhat smallish superheaters for their

size (Type A, 1425 square feet). These two items

would have restricted their "breathing" at high

speed by impeding the steam flow into and out of

the cylinders, resulting in a pressure drop from

the boiler to the cylinders. Later 4-8-4 designs

used 14 inch piston valves with even longer valve

travel and huge Type E superheaters to improve

their high-speed performance. Nonetheless, once

their balancing problems were corrected, the R-1's

were known as outstanding performers on the ACL

and their theoretical design deficiencies were not

seen as drawbacks when they were in service.

|