Planning Tips:

Plan, Plan, Plan. You should spend at least as much time

planning as building. I started planning in 1997 for my

layout and broke ground in 2000. I learned so much in

those three years, I can't imagine have starting any

earlier. In those 3 years I did things that didn't require

planning, so that once the track is laid down progress will go

quickly. You can build structures, locomotives, etc as you

plan the layout. Painting people and small details and

storing them until needed makes your layout really progress

quickly.

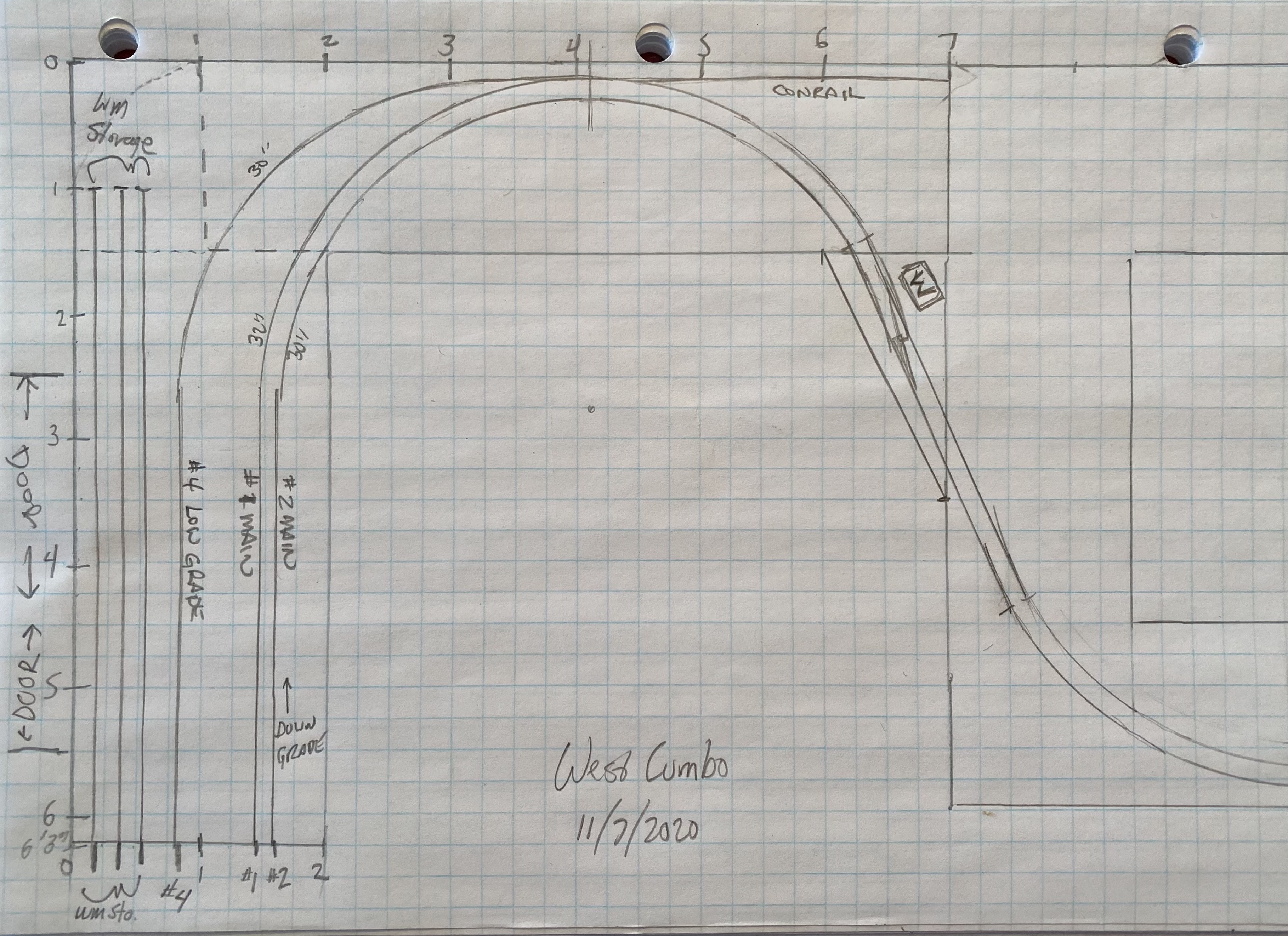

I also plan with graph paper and a track planning

template. This allows for lots of quick changes.

Additionally I save all the time not having to learn track

laying software. Below is a typical plan for my sections,

this one is Cumbo.

Building Tips:

Build the layout to be portable. I build in 4, 6 or 8 foot sections of varying width,

though most are 24 inches deep. The sections can then be

disconnected and moved if need be. I have relocated about

10 sections from my first house to my current house. This

has allowed me to continue work quickly in the new house and not

waste time, materials and money. As seen below, on the

middle section of Hancock, there are lots of advantages to

this. I can work on my saw horses at an ergonomic level,

saving my back. I can have 360 degree access to the

modeling area, so I don't have awkward reaches to do

scenery. I also can tip the whole section on its side and

do the wiring much easier. Additionally, I can move these

sections by myself, as each is under 10 lbs. Finally, if I

ever have to move again, I can just disconnect the track and

move this to the next house. This section already has been

moved between houses once. Also, to my note above, these

four structures were built prior to the layout and have now been

mounted into the foam.

Drill holes in your cross beams. I use 1x3

dimensional lumber to make the support structure for the

foam. I put a cross beam every 16 inches now for

rigidity. I didn't do that before, and some sections

flexed. I then drill 3/4 inch holes 6, 12 and 18 inches

from the front of the 24 inch wide layout. This will allow

you to put wires through the holes so they don't dangle below

the layout. Below you can see I drill three 3/4 inch holes

in the cross beams. The first photo is the west end of

Hancock section. I use the middle hole for the main power

bus for the DCC system (black and red wires). You can see

where the wires from each section of track drop though the foam

and connect to the main power bus wire. I used the hole

closest to the back of the layout for the switch machine wires

(not in this photo yet) The hole closest to the front will

be for LED light strings to illuminate the lower level.

The second photo shows under Martinsburg. The terminal

blocks (black squares or rectangles) are used to connect the

wires under each section, so they can easily be separated.

The green and white wires are for the switch motors. I

could have done this much neater, but I was running them while

the sections were mounted on the wall, which I will never do

again. Working under the layout is not comfortable.

Also, since this section sits near my DCC system, the grey flat

wire in the photo is the one that runs the tethered throttles.

Put the switch motors in from the top. In

each of my tower controlled interlockings (Brunswick,

Martinsburg, Cumbo, Miller and Hancock) I use Circuitron's

Tortoise Switch motors to electrically move each turnout.

I mount each Tortoise switch motor to a 4x4 inch piece of fascia

board. I then cut a hole in from the top of the foam and

mount it flush to the rest of the foam. You can see four

of them in the photo of Miller below (brown squares under the

turnouts). I did not do this years ago on my first

sections in Hancock. See the photo above and you won't see

the switch motors. This took considerable time to fix, but

I found a way to mount them from the bottom, and all of the

Hancock sections have been modified to have switch motors.

Trust me, it is WAY easier to put them in from the top, as you

build the track. Another tip from this photo, that I've

learned is to paint the foam dark grey before starting

work. I used to just start with the bare pink foam.

The pink is so distracting, that I couldn't stand it

anymore. Painting it grey also allows for better

protection for chipped scenery and is actually better to bond

plaster or scenery materials to.

Mount your building foundations before you build

the building. This is the foundation for the Hancock

passenger station. I made it first and mounted it in the

scenery, prior to building the rest of the building. This

has two main benefits. First, you can continue with

scenery in this area, while not having to wait for the rest of

the building. Second, your building will be removable,

making transport easier and reducing the chance of damage if it

gets bumped. I didn't do this on my early buildings, but

it is a standard practice now.

Start with the backdrop. I have done it

both ways, and trust me, it is much easier putting in the

backdrop first. I used both sheet styrene and hardboard

for my backdrops. I've found that hardboard backdrops

(which are a paper product) do better if you paint them on all

sides prior to installation. This keeps the swelling down

due to humidity changes through the seasons and helps eliminate

bubbles in your backdrop. The styrene or hardboard is

adhered with Liquid Nails to the wall. I also use 3M "90"

spray adhesive to adhere the backdrop itself to the styrene or

hardboard, which I have found is much better than their "77"

product. I also cove the corners, by bending the styrene

or hardboard, avoiding a harsh sharp corner on the layout.

These images show Miller on the upper left and Cumbo on the

upper right. Note the Brunswick (lower left) backdrops are

already installed, but benchwork construction hasn't begun there

yet.